Roller clutches / Roller clutches

1) This description is for informational purposes only and we assume no responsibility for any inaccuracies, errors, etc.

2) The weight of less than 0.001 kg is indicated as 0.001 kg

3) The sketch does not contain all the design features of the productGo to purchase

Drawn cup roller clutches INA HF1416 L564

| Brand | Country of origin of the brand |

|---|---|

| INA | Germany |

The dispatch of the goods is carried out within 1-2 banking days from the order day!

Look at the prices for analogues-substitutes:

| Name | Brand | Photo | Video | Dimensions | Price / Availability |

|---|---|---|---|---|---|

|

Drawn cup roller clutches Drawn cup roller clutches CX HF1416 |

CX |

|

F: 14 D: 20 C: 16 Analogues |

56 грн.

Are available

|

Look at the prices for analogues-substitutes:

| Notation | Brand | Photo | Dimensions | Price for 1 pc. / Availability |

|---|---|---|---|---|

|

Drawn cup roller clutches Drawn cup roller clutches CX HF1416 |

CX |

|

F: 14 D: 20 C: 16 Analogues |

56 uah

Are available |

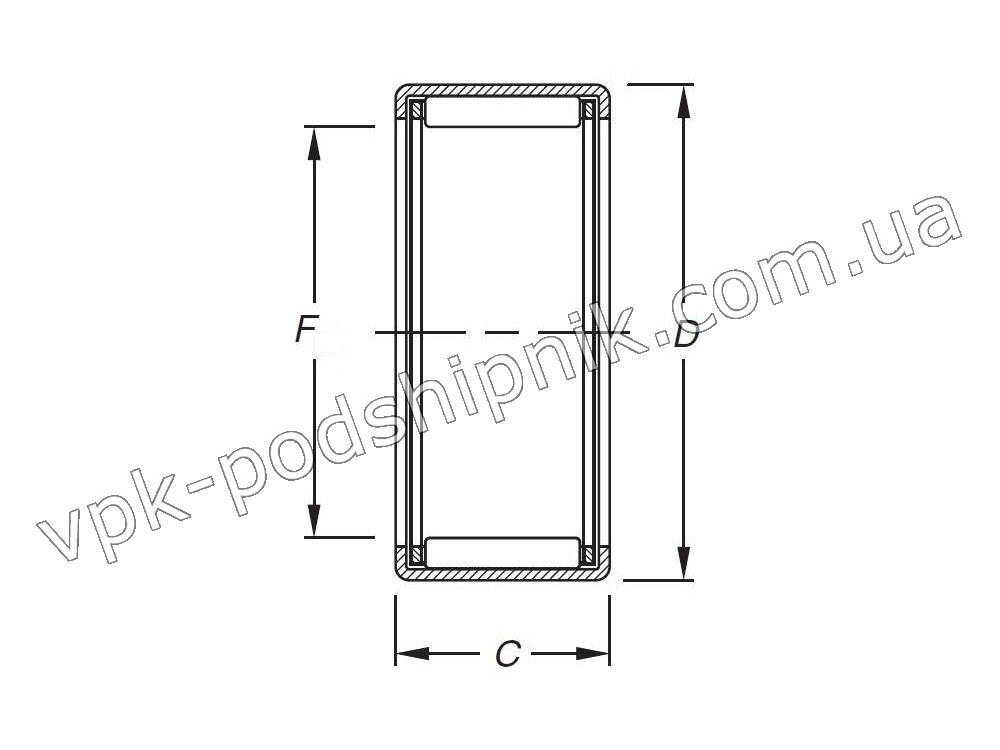

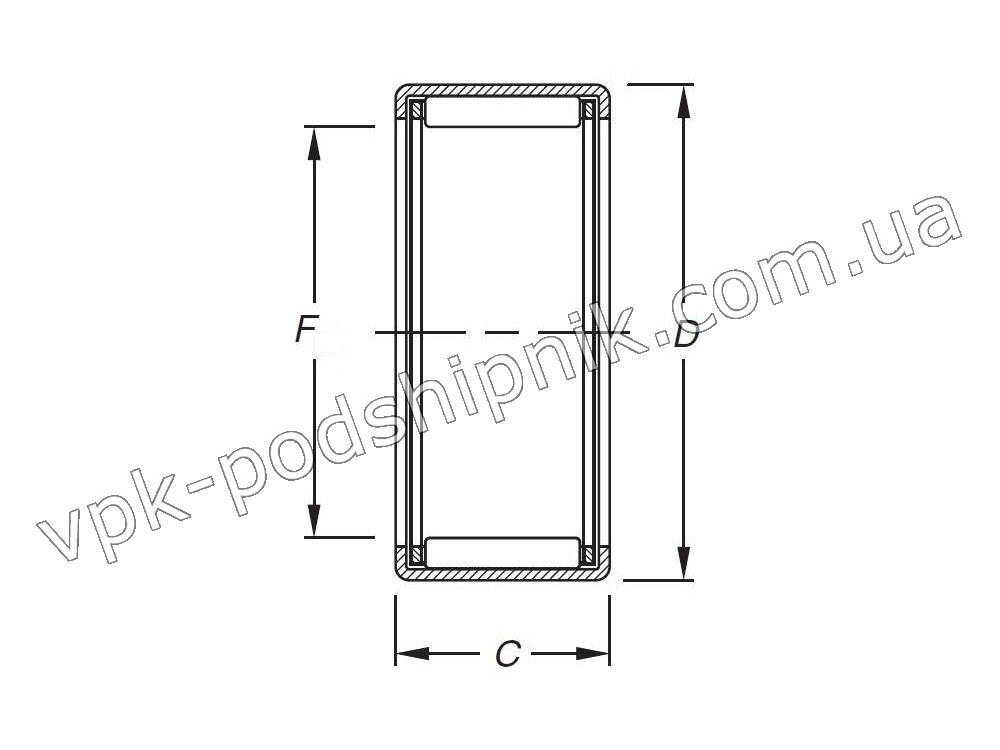

Sketch

Characteristics:

(INA HF1416 L564)

| Diameter under rollers F | F | 14 | mm |

| Bearing outside diameter D | D | 20 | mm |

| Height (width) of the outer ring of the bearing C | C | 16 | mm |

| Permissible torque | MDper | 17.3 | Nm |

| Shaft speed limit (valid for grease and oil lubrication) | ngw | 8.1 | r/min |

| Outer ring speed limit (valid for grease and oil lubrication) | nga | 9500 | r/min |

| Suitable drawn cup needle roller bearings for radial bearing arrangement | Array | HK1416 | Array |

| 0.013 |

2) The weight of less than 0.001 kg is indicated as 0.001 kg

3) The sketch does not contain all the design features of the product

Application

Drawn cup roller clutches with steel springs:- one-way couplings that transmit only torque in one direction, therefore, they must be used on the same shaft with rolling or sliding bearings, which will perceive a radial load,- available with or without integrated bearing unit,- give very accurate indexing,- allow high indexing frequencies,- have a low overrunning friction torque,- available with or without lubrication,- are particularly compact in the radial direction and therefore allow extremely compact designs,- suitable for body materials made of steel, light metal or plastic,- can be combined with pressed cup needle roller bearings with open end HK and closed end BK- have a wide range of applications, such as indexing clutches, backstop clutches and freewheel clutchesThey consist of thin-walled, stamped outer rings with a number of inclined sections along the inner diameter, plastic cages and needle rollers that serve as clamping elements. Steel or plastic springs hold the needle rollers in a clamped position. Roller couplings can transmit high torques in one direction and are particularly compact in the radial direction. Roller couplings are available with or without journal bearings. Correct operation of such couplings can only be guaranteed if the alignment error between the thrust bearing and the shaft can be kept low.