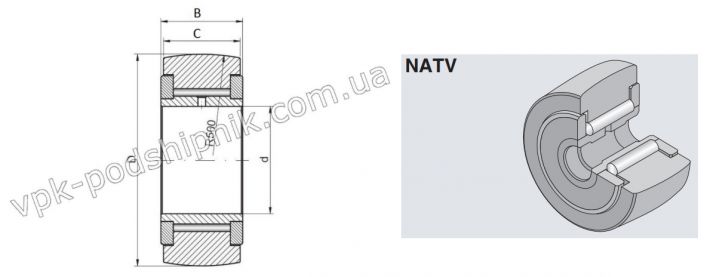

NATV support rollers

Support rollers NATV - without separator (with a full set of rollers), with axial centering, the standard version has an outer ring with a spherical surface, synthetic rubber seals (suffix LL) on both sides, filled with lithium soap grease (suffix 3AS). This type of support rollers can be used in the temperature range from 20 to + 120 C or can be used continuously at a temperature of 100 C or lower. Feed and add lubricant to the bearing through a special hole for lubrication, which is located on the inner ring. The inner ring in this case is set so properly that the lubrication hole is outside the load zone. For NATV type rollers with a full set of igorolikov that are installed without a separator (in bulk, right next to each other) it is necessary to reduce the time between lubrications. These bearings are able to cope with large radial loads due to the thick-walled outer ring. It is this thick-walled version of the outer ring that allows to reduce the deformations and reduce the bending stresses. When the support roller moves along the guide surface, the distortion of the outer ring and the increase in the edge tension are not excluded. To keep it to a minimum, the outer ring is spherical on the outside. All these technical solutions increase the service life of the support roller and the assembly as a whole. The most massive use of the type of support rollers NATV received on conveyors and technological automatic lines.

All articles