Longitudinal bearings

Linear Motion Bearings (they are ball bushings) video of one of the bearings is presented on the channel![]() most often used in mechanical engineering and industrial production. Having replaced conventional rolling bearings, they not only reduced the friction force on the shaft, but also ensured a smooth translational motion. The latter is important for such mechanisms as machine tools, where high accuracy of movement and compliance with a given trajectory is necessary.

most often used in mechanical engineering and industrial production. Having replaced conventional rolling bearings, they not only reduced the friction force on the shaft, but also ensured a smooth translational motion. The latter is important for such mechanisms as machine tools, where high accuracy of movement and compliance with a given trajectory is necessary.

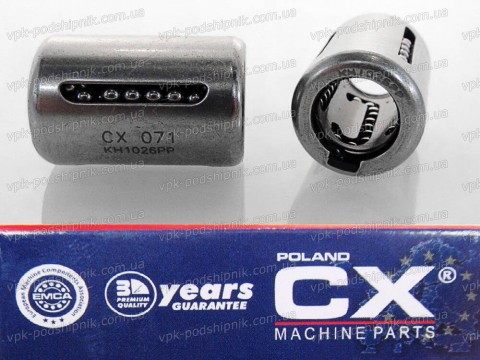

Linear bearings are a polyamide cage, in which the raceways (mainly made of stainless steel) with sets of balls are segmented. The recycling of the balls does not resist the separator and does not lead to a runout, and their size makes it possible to carry heavy loads. This design allows you to fully use the load zone, increasing the carrying capacity and increasing the durability of the node. Regardless of the length of the movement, such bearings provide minimal friction along the guide, they are compact and easy to install. The main condition when installing a bearing is to precisely align its alignment with the housing or shaft.

Various linear bearing options: LM, LBAS, KH, KB series

The variant of both open and closed bearing of longitudinal movement is possible. Closed, more sealed, protected from grease leakage and contamination by a double-lip seal. Open also have some protection in the form of contactless shields that prevent the ingress of large debris. As in any other bearing, in the closed version, the lubricant is applied at the factory, and in no case should it be opened and re-lubricated. Linear guides SKF shafts are lubricated with LGEP2 special grease that can withstand high loads, temperatures ranging from -30 ° C to + 110 ° C and having anti-corrosion properties.

Longitudinal bearing most often used in the automotive and food industries; in the automation of production and processing machines; in medical equipment where high precision of work is required (for example, optical devices); in robotics. Also recently, the use of these bearings in homes and offices is gaining popularity, for example, when constructing sliding structures.

The main advantages of sliding sleeve bushings are high accuracy and rigidity of construction, smooth movement combined with high bearing capacity and long service life.

All articles