Replacing the V-belt: how not to make a mistake

V-belts widely used in drives of agricultural and industrial machinery. They transfer torque between the pulleys, driving the mechanism.

Sooner or later there comes a time when the belt loses its normal performance. Even with perfect alignment of the pulleys, cleanliness of the knot and the use of expensive high-quality products such an outcome, alas, can not be avoided.

The reasons for the failure of the belt a lot. It is possible to break even after short-term use - due to the blocking of the drive, improper installation or the ingress of foreign objects. The lateral edges wear out quickly if the tension is too low and the starting torque is too high, as well as when the pulleys are misaligned. Cracks in the base of the belt appear mainly when installed on a pulley with a diameter less than the recommended, when slipping and non-compliance with the temperature. The belt can also become sticky or sticky to the touch when exposed to chemical or oily (oily) substances. Strong vibrations, too little tension or misalignment of the pulleys may cause the belt to twist.

In all these situations, the question of replacing the V-belt arises, and here it is important to choose the right one. If marking remains on the surface, this greatly simplifies the situation. In this case, you just need to find exactly the same.

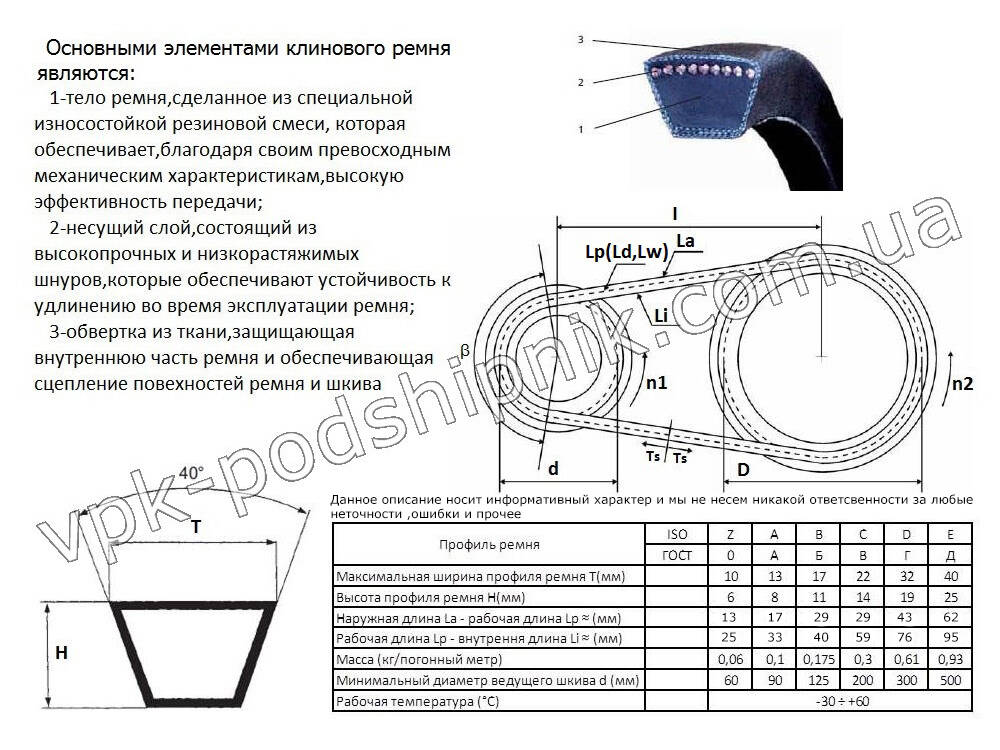

Marking V-belts consists of a profile and length.

The profile of the V-belt (denoted by a letter) is its standard geometrical characteristics: maximum width and height, minimum allowable diameter of the driving pulley. Belt length (digital value) is the nominal estimated length in millimeters.

Usually the buyer does not have any questions about the length of the belt, but with its labeling can be difficult. The fact is that the designation of V-belts can be either in the GOST system (CIS countries, earlier - the USSR), or in the international ISO system. Consider the ratio of markings in various standards:

| Belt profile | ||||||

|---|---|---|---|---|---|---|

| GOST | 0 | А | Б | В | Г | Д |

| ISO | Z | A | B | C | D | E |

| Section width, mm | 10 | 13 | 17 | 22 | 32 | 40 |

Most commonly used belt profile B (B) и belt profile C (B). Distinguish the Latin letter "B" from the Cyrillic "B" on the move will not work. But, having lost sight of this moment, you can order the wrong belt that you need, and in the end spend extra money and, importantly, time!

In order not to be mistaken, one should measure the width of the belt section. If it is 17 mm, then the desired belt will be profile B (B), if 22 mm, then profile C (C).

If belt marking erased, or it is worn out so that it is not possible to read it, the profile can be calculated again by the width of the section, just enough to measure the width of the pulley. The length can be calculated by wrapping the pulleys on the drive with a rope, and then adding the corresponding standard value to the measured one (see the line “Working length Lp - internal length Li” in the picture below).

The company MIC-Bearing is a wide V-belt catalog that will help you choose exactly what you need.

All articles